South Korea Leads the Charge in Robotic Workforce Transition

In a fascinating shift towards automation, a recent survey conducted by the International Federation of Robotics (IFR) reveals that over 10% of South Korea’s workforce has been replaced by robots. The 2024 World Robotics report shows that South Korea is at the forefront of this robotic revolution, boasting a remarkable 1,012 robots per 10,000 employees.

The Rise of Robotics in South Korea

Since 2018, South Korea has ramped up its robot adoption rate by 5% each year, solidifying its status as a leader in the global shift towards automation. With its advanced technology and manufacturing capabilities, the country stands as a benchmark for others looking to enhance efficiency through robotics.

Robot adoption in factories around the world continues at a rapid pace, according to the World Robotics 2024 report, presented by the International Federation of Robotics (IFR).

A Global Perspective on Robot Density

How does South Korea compare to other countries? Following South Korea, Singapore ranks second with 770 robots per 10,000 employees. China has moved into third place with 470, surpassing Germany and Japan, which are fourth and fifth with 429 and 419 robots per 10,000 employees, respectively. The United States comes in at tenth place with just 295 robots per 10,000 employees.

This data paints a vivid picture of the global landscape of robotic integration in workplaces.

Regional Breakdown: Who’s Embracing Automation?

Here’s a closer look at robot density by region:

- European Union: 219 robots per 10,000 employees (5.2% increase)

- North America: 197 robots per 10,000 employees (4.2% increase)

- Asia: 182 robots per 10,000 employees in manufacturing (7.6% increase)

Countries such as Germany, Sweden, Denmark, and Slovenia are experiencing significant growth in robotic adoption, placing them among the top ten most automated nations globally.

Real-Life Impact of Robotics

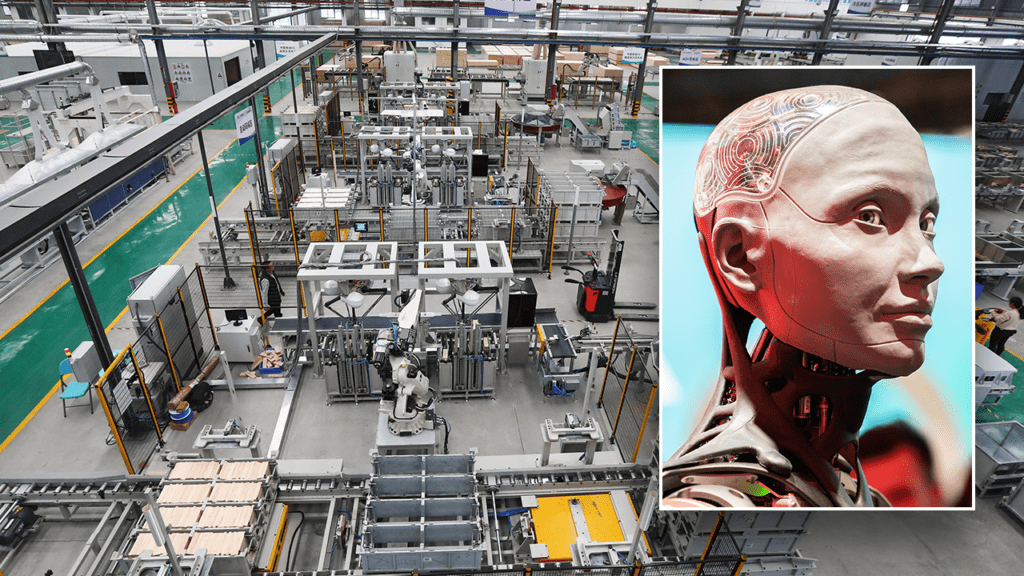

Imagine walking into a state-of-the-art factory where robots are diligently assembling products with precision while humans oversee operations with tablets in hand. This is the new norm, where automation not only enhances productivity but also liberates workers from monotonous tasks, allowing them to focus on more complex and engaging responsibilities.

For instance, a manager in Germany might utilize robot arms for routine assembly tasks, overseeing the process and ensuring quality instead of being stuck in the nitty-gritty of production. It’s not just a technological shift; it’s a cultural transformation in how work is perceived and executed.

Conclusion: The Future of Our Workplaces

As robotics technology advances, we can expect profound changes across various sectors, with countries like South Korea leading the way. The rise in automation offers exciting opportunities, reshaping how we work and live.

The AI Buzz Hub team is excited to see where these breakthroughs take us. Want to stay in the loop on all things AI? Subscribe to our newsletter or share this article with your fellow enthusiasts.