Surge in AI and Machine Learning Adoption Among Manufacturers, Universal Robots Survey Reveals

The artificial intelligence (AI) sector is projected to reach a staggering $407 billion by 2027, growing at an annual rate of 37.3%, according to Forbes. Universal Robots A/S (UR) recently conducted a survey among nearly 1,200 manufacturers in North America and Europe to assess their current use of AI technologies and future investment intentions in this rapidly evolving market.

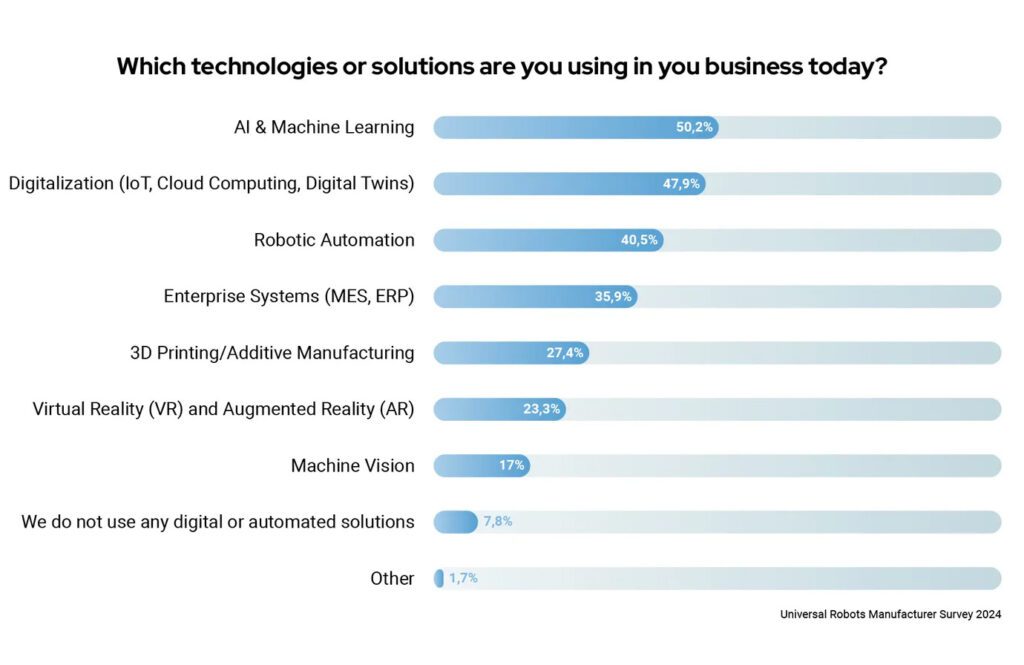

More than half of the respondents reported that they are already implementing AI and machine learning within their production processes. "AI isn’t just hype," emphasized Anders Billesø Beck, UR’s Vice President for Strategy and Innovation. He noted that the prominence of AI in discussions has surged in the past two years, making it a fundamental component of innovation and efficiency within modern manufacturing.

Looking ahead, nearly half (48%) of manufacturers expressed plans to increase their investments in AI and machine learning by 2025, suggesting these technologies will continue to shape the manufacturing landscape significantly. The survey, conducted with a confidence rate of 99%, included participants from seven countries across Europe and North America and represented a mix of 569 large enterprises and 278 small to mid-sized companies.

According to UR’s findings, AI and machine learning are increasingly recognized as essential for both current operations and future growth. The company anticipates that AI-driven robotic systems will become more widespread across various industries.

Key Insights from the UR Survey

The survey results highlighted the growing significance of digitalization, with 47% of manufacturers currently using tools like the Internet of Things, cloud computing, and digital twins. These technologies facilitate operational optimization, minimize downtime, and lead to cost savings through enhanced simulations and predictive maintenance, enabling companies to adapt to more resilient and agile production models.

Manufacturers reported several motivations for adopting new technologies, with over 50% citing improvements in product quality, increased productivity, and enhanced accuracy. UR interprets these findings as a strong commitment from the industry towards leveraging robotics and AI for better performance and competitive edge.

Interestingly, 30% of surveyed manufacturers are deploying technology to enhance working conditions, while 26% are motivated by sustainability objectives. However, concerns about return on investment (ROI) still loom large, with 32% of manufacturers identifying it as their primary worry. Other significant concerns—each around 20%—include usability, in-house expertise, safety, and potential operational disruptions.

As the adoption of automation and AI accelerates, ease of use emerges as a priority for manufacturers. A substantial 47% indicated that the straightforward integration and operation of technologies are of utmost importance to them, followed closely by reliability and factors such as modularity, sustainability, rapid deployment, and predictive maintenance.

Upcoming Events

Eric Truebenbach, Managing Director of Teradyne Robotics Ventures, will be discussing the future of robotics innovation and investment trends at RoboBusiness 2024, scheduled for October 16 and 17 in Santa Clara, California. Teradyne is the parent company of both Universal Robots and Mobile Industrial Robots.

For those interested in robotics, registration for the 2024 RoboBusiness is now open.