Embracing Industry 4.0: Transforming Electrical Manufacturing for the Future

In the fast-paced world of industrial manufacturing, adapting to new technological trends is no longer a choice—it’s a necessity. The emergence of Industry 4.0 and the Internet of Things (IoT) is revolutionizing the manufacturing sector, paving the way for enhanced efficiency, productivity, and profitability. For electrical system manufacturers, leveraging these innovations is crucial in maintaining a competitive stance.

Key Areas for Manufacturers to Focus

-

Revolutionizing the Value Chain:

Industry 4.0 has the potential to redefine manufacturing from a mere cost center into a dynamic profit driver. By harnessing the capabilities of IoT, interconnected systems, and cyber-physical systems, manufacturers can achieve unprecedented operational flexibility and efficiency. These advanced technologies facilitate real-time data sharing across all stages of production, leading to improved decision-making processes and minimized downtime. -

Optimizing Operational Processes:

Manufacturers can optimize every phase of production, from design to logistics. Utilizing cutting-edge tools such as digital twins and simulation software enables companies to refine processes in a virtual environment, significantly reducing errors and expediting time-to-market. -

Boosting Efficiency:

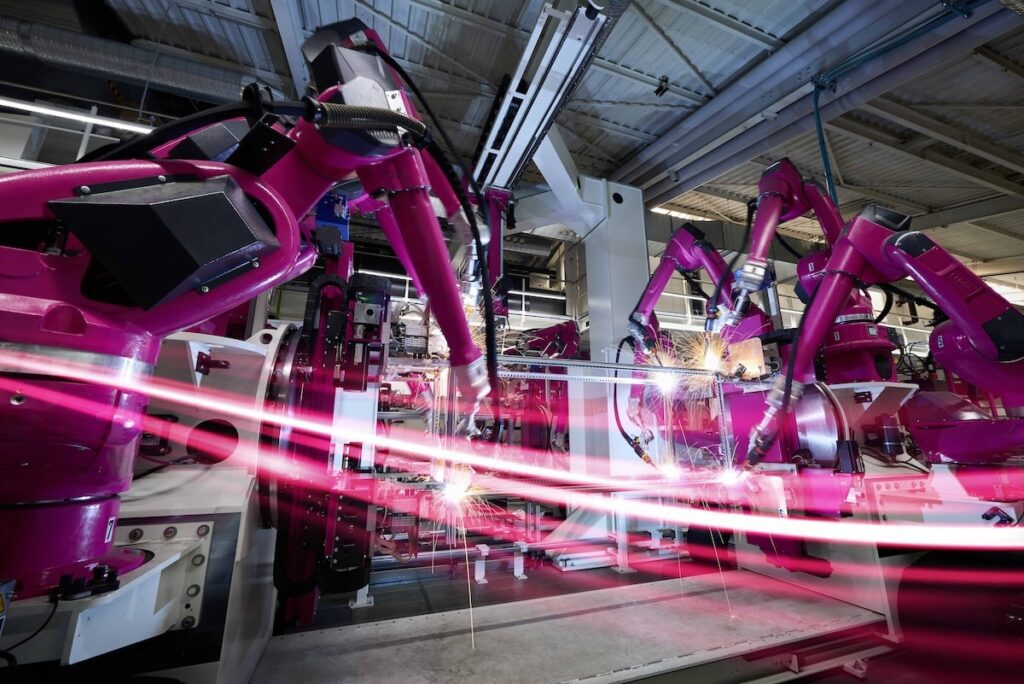

Picture slashing engineering design time in half, minimizing production errors, and simplifying your operations. With the capabilities brought forth by Industry 4.0 technologies, such as state-of-the-art computer-aided engineering (CAE) software and automation solutions, these enhancements are readily achievable. Automation not only streamlines repetitive tasks but also improves consistency and quality, providing the means to deliver superior products at reduced costs. - Gaining a Competitive Advantage:

Companies that have embraced Industry 4.0 are reaping substantial rewards, including heightened efficiency, lowered operational costs, and increased adaptability. By standardizing procedures and adopting automation, these manufacturers stand better equipped to meet market demands swiftly, thereby gaining an edge over competitors. The ability to finely tune operations in response to changing conditions is vital in today’s rapidly evolving market landscape.

Rittal: Pioneering the Industry 4.0 Transformation

Rittal is at the forefront of the Industry 4.0 movement, offering solutions that seamlessly integrate into modern manufacturing practices. Their cutting-edge technologies are designed to enhance real-time design and production, leveraging advanced digital twin technologies that revolutionize operational methodologies.

For access to deeper insights on future-proofing your manufacturing processes, consider downloading Rittal’s in-depth white paper, “Going Up the Value Chain,” to kickstart the optimization of your operations.

Download the white paper here: Going Up the Value Chain

Conclusion

As manufacturers navigate the complexities of the modern industrial era, the adoption of Industry 4.0 principles is not merely advantageous but essential. By embracing advanced technologies, manufacturers can transform their operations into efficient, data-driven systems that thrive in a competitive landscape. The future of electrical systems manufacturing is bright for those willing to innovate and adapt—now is the time to take action!