A Complete AWS ML Solution with SageMaker, Lambda, and API Gateway

Introduction

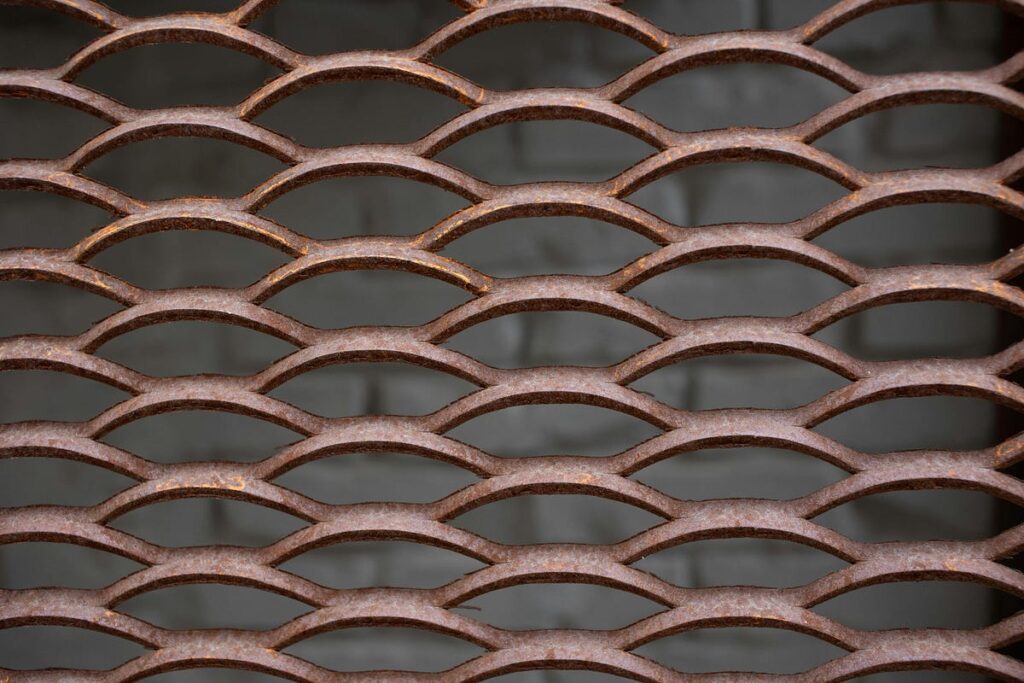

In industries like manufacturing, energy, and telecommunications, ensuring operational efficiency is paramount. One critical factor that threatens this efficiency is corrosion, a natural process that gradually deteriorates metal components due to environmental influences. If not properly managed, corrosion can result in dangerous health conditions, costly machinery downtimes, and even infrastructure failures.

This article explores an innovative and fully automated approach to corrosion detection by harnessing the power of cloud computing. Through Amazon SageMaker, Lambda, and API Gateway, we can create a scalable and reliable quality control system that detects corrosion effectively and efficiently.

Data

For our project, we tapped into the Synthetic Corrosion Dataset (CC BY 4.0), which comprises a wealth of synthetic images—each categorized as either "Corrosion" or "Not Corrosion." An added bonus? The dataset is already organized into training, validation, and testing folders, eliminating unnecessary splitting. The specifics are impressive: 270 images for training, 8 for validation, and 14 for testing.

Optimizing the Detection Process

Automation in detecting corrosion can be a game changer. With traditional methods often leading to human error, adopting a machine learning approach helps reduce these risks while increasing the accuracy and speed of detection. By applying Amazon SageMaker, we can easily build and train models that analyze the images from the dataset.

Here’s how it works:

- Data Preparation: Import the dataset into SageMaker, ensuring the images are in the right format.

- Model Training: Utilize SageMaker’s powerful algorithms to train our model, allowing it to learn the differences between corroded and non-corroded images effectively.

- Testing and Validation: Once the model is trained, it’s crucial to test its accuracy using the validation set and adjust parameters as needed.

- Deployment: Finally, we deploy the model using AWS Lambda and API Gateway for a seamless integration that enables automatic calls to the model for real-time corrosion detection.

Real-Life Application

Consider a manufacturing plant dealing with a constant threat of machinery wear due to corrosion. Implementing this automated solution means that the plant can receive immediate alerts when corrosion is detected, thereby scheduling maintenance proactively and preventing costly downtimes.

Imagine this scenario: A critical piece of machinery begins to show signs of wear and tear. Instead of waiting for routine inspections, the system alerts the maintenance team almost instantly, allowing them to intervene before the situation escalates. That’s the kind of efficiency which modern technology can bring to the table!

Conclusion

In wrapping up, embracing cloud computing tools like Amazon SageMaker, Lambda, and API Gateway not only propels industries into the future but also enhances their capabilities to manage corrosion, thereby safeguarding operational integrity. This innovative approach can be adapted across various sectors, ensuring machinery remains reliable and effective.

The AI Buzz Hub team is excited to see where these breakthroughs take us. Want to stay in the loop on all things AI? Subscribe to our newsletter or share this article with your fellow enthusiasts.