Foxconn Embraces Humanoid Robots to Boost iPhone Production

In a bold move to enhance production efficiency, Foxconn has entered into a long-term partnership with UBTech, a leading robotics company, to incorporate more humanoid robots into its iPhone manufacturing processes. As smartphone production becomes increasingly intricate, these advanced machines are poised to improve the precision and reliability of tasks involving the most delicate components.

The Rise of Humanoid Robots in Manufacturing

According to a report from the South China Morning Post, Michael Tam, UBTech’s Chief Brand Officer, emphasized the need for robots to expand their skill sets tailored specifically for modern manufacturing demands. “For car manufacturing, there [are] thousands of tasks on our list,” he noted. “In areas like 3C production (computers, communication, and consumer electronics), [there are] totally new skills for humanoid robots to learn.”

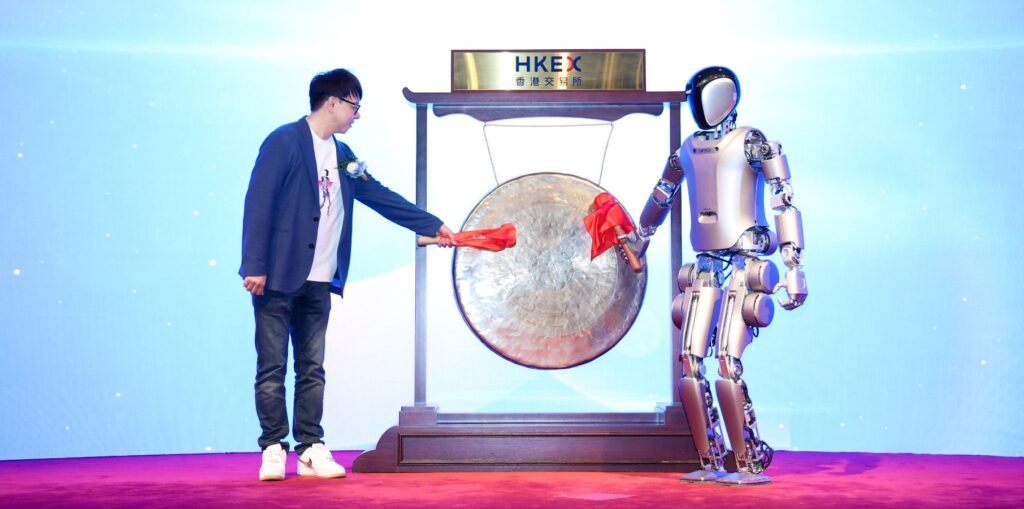

One of the standout innovations from UBTech is the Walker S1 humanoid robot. After successfully completing two months of training in logistics at Foxconn’s factories in Shenzhen’s Longhua district, the Walker S1 is set to transition to Foxconn’s automotive manufacturing plant in Zhengzhou city. While there’s excitement about an upcoming S2 version of the humanoid robot, the timeline for its deployment in iPhone production remains uncertain.

A Different Approach to Supply Chain Diversification

Apple has been proactive in diversifying its supply chain to mitigate the manufacturing challenges it encountered during the iPhone 14 launch in 2022. Back then, a surge in COVID-19 cases at Foxconn’s main factory, coupled with worker protests, prompted Apple to seek alternative manufacturing avenues in India and other Asian nations.

As part of this strategic shift, the iPhone 17 models are expected to launch simultaneously from Foxconn’s factories in multiple regions, including China and India, by 2025. This marks a significant change, as previous years saw Indian factories rolling out new iPhone models several weeks after the global debut.

The Future of Robotics at Foxconn

The infusion of humanoid robots into Foxconn’s operations could be a game-changer in improving efficiency, reducing costs, and enhancing the overall quality of production. Their capacity to handle complex tasks promises to streamline various stages of the manufacturing process, ultimately leading to faster and more reliable iPhone production.

As the technology evolves, it will be fascinating to watch how these robots adapt and contribute to Foxconn’s production lines, particularly in the dynamic landscape of consumer electronics.

In conclusion, the introduction of humanoid robots marks an exciting chapter for Foxconn and the broader manufacturing industry. The AI Buzz Hub team is excited to see where these breakthroughs take us. Want to stay in the loop on all things AI? Subscribe to our newsletter or share this article with your fellow enthusiasts.